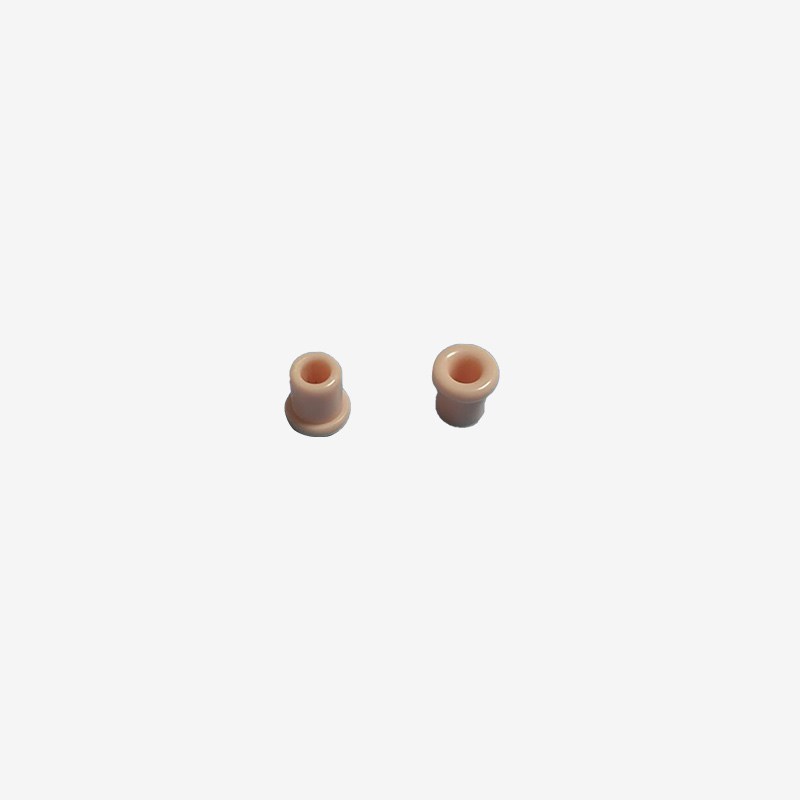

Alumina Ceramic Ib feem ntawm Textile Machinery

Daim ntawv thov teb

Textile ceramics qhov chaw uas tau siv dav hauv textile machinery nrog cov cuab yeej siv siab, siab tawv, hnav ntev, rwb thaiv tsev loj, tiv thaiv corrosion zoo, kub resistant.

Textile ceramics qhov chaw muaj ntau yam kev siv hauv lub neej txhua hnub.Peb hais tias almonia ceramics qhov chaw tuaj yeem siv rau hauv cov txheej txheem xws li xov paj interlacing, kos duab, spinning, plasticization, weaving, thiab knitting thiab lwm yam.Tuam Tshoj yog lub lag luam loj tshaj plaws ntawm textile ceramics qhov chaw.Tsis tas li ntawd, kev sib tw hauv tsev textile ceramic accessories kev lag luam kuj tseem hloov pauv tas li.

Qee cov lag luam hauv tsev tau maj mam txo qhov sib txawv nrog cov khoom lag luam txawv teb chaws los ntawm kev tshawb fawb thiab kev tsim kho thiab kev txhim kho kom zoo, thiab lawv txoj kev lag luam tau maj mam nce.Nyob rau tib lub sijhawm, qee lub npe txawv teb chaws tau maj mam nkag mus rau hauv Suav lag luam, ntxiv kev txhawb nqa kev lag luam textile ceramic accessories.

Paub meej

Quantity yuav tsum:1pc rau 1 lab pcs.Tsis muaj MQQ txwv.

Lub sij hawm ua piv txwv:tooling ua yog 15 hnub + qauv ua 15 hnub.

Lub sijhawm ua khoom lag luam:15 mus rau 45 hnub.

Lub sij hawm them nyiaj:sib tham los ntawm ob tog.

Txheej txheem ntau lawm:

Alumina (AL2O3) ceramic yog ib qho kev lag luam ceramic uas muaj siab hardness, ntev hnav, thiab tsuas yog tsim los ntawm pob zeb diamond sib tsoo.Nws yog tsim los ntawm bauxite thiab ua tiav los ntawm kev txhaj tshuaj molding, nias, sintering, sib tsoo, sintering thiab machining txheej txheem.

Physical & Chemical Data

| Alumina Ceramic (AL2O3) Daim Ntawv Qhia Cov Cim | |||||

| Kev piav qhia | chav tsev | Qib A95% | Qib A97% | Qib A99% | Qib A99.7% |

| Qhov ntom | g/cm3 | 3.6 | 3.72 ib | 3.85 ib | 3.85 ib |

| Flexural | Mpa | 290 | 300 | 350 | 350 |

| Compressive zog | Mpa | 3300 ib | 3400 ib | 3600 ib | 3600 ib |

| Modulus ntawm elasticity | Gpa | 340 | 350 | 380 | 380 |

| Kev cuam tshuam tsis kam | Mpm 1/2 | 3.9 | 4 | 5 | 5 |

| Weibull Modulus | M | 10 | 10 | 11 | 11 |

| Vickers hardulus | hwv 0.5 | 1800 | 1850 | Xyoo 1900 | Xyoo 1900 |

| Thermal Expansion coefficient | 10-6k-1 ib | 5.0-8.3 | 5.0-8.3 | 5.4-8.3 | 5.4-8.3 |

| Thermal conductivity | W/Mk | 23 | 24 | 27 | 27 |

| Thermal shock Resistance | △ T ℃ | 250 | 250 | 270 | 270 |

| Max siv kub | ℃ | 1600 | 1600 | 1650 | 1650 |

| Volume resistivity ntawm 20 ℃ | Ω | ≥1014 | ≥1014 | ≥1014 | ≥1014 |

| Dielectric zog | KV/mm | 20 | 20 | 25 | 25 |

| Dielectric tsis tu ncua | ε r | 10 | 10 | 10 | 10 |

Ntim

Peb feem ntau siv cov khoom siv xws li dej-pov thawj, poob siab-pov thawj rau cov khoom uas yuav tsis puas.Peb siv PP hnab thiab thawv ntoo pallets raws li tus neeg yuav tsum tau muaj.Haum rau kev thauj mus los hauv hiav txwv thiab huab cua.